Designing 3D Packaging Prototypes: From Concept to Physical Sample

The Genesis of an Idea

3D Packaging design is a crucial aspect of product development. It’s the first physical interaction a customer has with a product, and it plays a significant role in shaping their perception of the brand and the item inside. Creating effective packaging goes far beyond just aesthetics; it involves functionality, protection, sustainability, and cost-effectiveness. The process of moving from an initial concept to a tangible 3D prototype is a complex one, requiring careful planning, skilled execution, and a deep understanding of materials and manufacturing processes.

The starting point is always the idea. What is the product? Who is the target audience? What are the key selling points? What are the regulatory requirements? These questions, and many others, form the foundation of the design brief. This brief serves as a roadmap, guiding the design team through the subsequent stages. It should clearly outline the product’s dimensions, weight, fragility, and any specific handling requirements. The marketing goals, branding guidelines, and desired shelf appeal are also crucial components of this initial document. A well-defined brief prevents costly revisions and ensures that the final packaging aligns with the overall product strategy.

Sketching and Conceptualization

Once the design brief is finalized, the creative process begins. Designers often start with hand-drawn sketches, exploring different shapes, forms, and opening mechanisms. This stage is about generating a wide range of possibilities, without being constrained by technical limitations. It’s a free-flowing exploration of ideas, where quantity often leads to quality. The best sketches are then refined, incorporating feedback from the design team, marketing department, and potentially even focus groups.

These refined sketches provide a visual representation of the packaging concept, but they lack the depth and detail needed for manufacturing. This is where computer-aided design (CAD) software comes into play. Using specialized programs, designers translate the 2D sketches into 3D models. This allows for a much more precise visualization of the packaging, enabling the team to assess its proportions, ergonomics, and overall aesthetic from all angles.

Digital Modeling and Refinement

The 3D CAD model is far more than just a pretty visual. It’s a virtual prototype that can be manipulated, tested, and refined with incredible precision. Designers can experiment with different materials, wall thicknesses, and closure systems, all within the digital environment. This iterative process allows for rapid prototyping, significantly reducing the time and cost associated with traditional methods.

The digital model also facilitates collaboration. Different stakeholders, including engineers, manufacturers, and marketing professionals, can access and review the design, providing feedback and suggestions in real-time. This collaborative approach helps to identify potential problems early on, preventing costly mistakes down the line. For example, an engineer might point out that a particular design feature would be difficult or expensive to manufacture, prompting the designer to make adjustments.

Choosing the Right Materials

The selection of materials is a critical decision in packaging design. The material must provide adequate protection for the product during shipping and handling, while also being cost-effective and aligned with the brand’s sustainability goals. Common packaging materials include cardboard, corrugated fiberboard, plastics, and various types of films. Each material has its own unique properties, strengths, and weaknesses.

Cardboard, for instance, is a relatively inexpensive and versatile material, often used for secondary packaging (boxes that contain multiple units of a product). Corrugated fiberboard, with its layered construction, offers greater strength and cushioning, making it suitable for shipping heavier or more fragile items. Plastics, while offering excellent barrier properties and design flexibility, are increasingly under scrutiny due to environmental concerns. Bio-plastics and other sustainable alternatives are gaining traction, offering a more environmentally friendly option. The choice of material also impacts the printing and finishing options available.

The Printing and Graphics Phase

Once the structural design and materials are finalized, the focus shifts to the visual elements of the packaging. This includes the graphics, colors, typography, and any other visual cues that communicate the brand’s message and attract the consumer’s attention. The printing process itself can vary depending on the chosen material and the desired effect.

Common printing methods include offset lithography, flexography, and digital printing. Offset lithography is a high-quality printing process often used for large print runs, producing sharp images and vibrant colors. Flexography, which uses flexible relief plates, is well-suited for printing on a variety of substrates, including corrugated board and flexible films. Digital printing offers greater flexibility for short runs and variable data printing, allowing for customization and personalization. The graphic design must not only be visually appealing but also comply with any labeling regulations and provide clear and concise product information.

Prototyping: Bringing the Design to Life

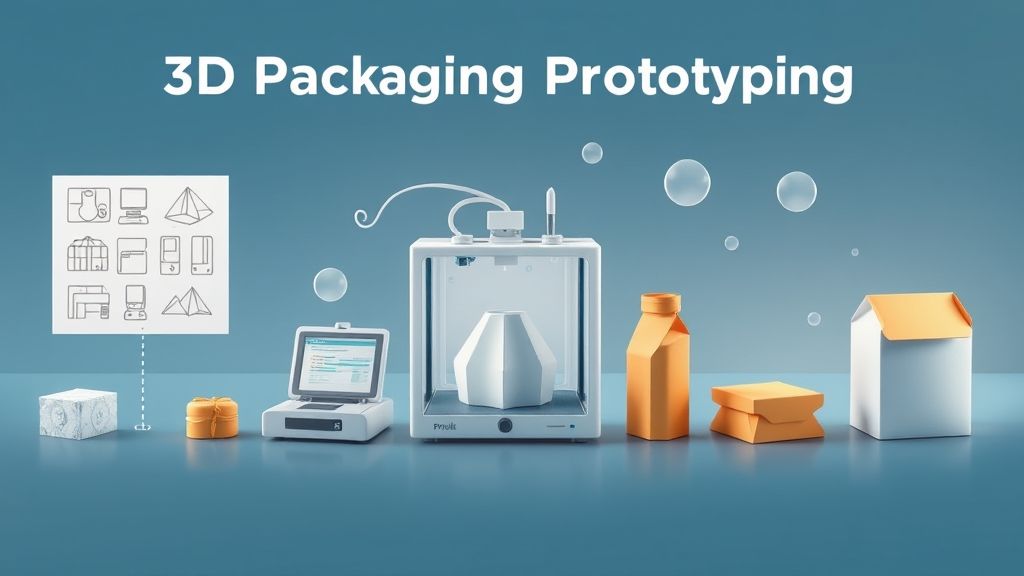

With the digital model and graphic design complete, the next step is to create a physical prototype. This is a crucial stage, as it allows the design team to evaluate the packaging in the real world, assessing its functionality, ergonomics, and overall appearance. There are several methods for creating 3D packaging prototypes, ranging from simple hand-made mockups to sophisticated 3D-printed models.

For simple box shapes, a prototype can often be created using cardboard, scissors, and adhesive. This allows for a quick and inexpensive way to assess the basic form and fit of the packaging. For more complex shapes or designs requiring greater precision, 3D printing is often the preferred method. 3D printing, also known as additive manufacturing, allows for the creation of highly detailed and accurate prototypes directly from the CAD model.

Testing and Evaluation

The physical prototype is subjected to a series of tests to ensure it meets all the required specifications. These tests can include drop tests, compression tests, and vibration tests, simulating the rigors of shipping and handling. The prototype is also evaluated for its ease of use, including opening, closing, and dispensing of the product.

User feedback is also crucial at this stage. Potential customers may be asked to interact with the prototype, providing valuable insights into its usability and overall appeal. This feedback can be used to make further refinements to the design, ensuring that the final packaging is both functional and consumer-friendly. Any issues identified during testing, weather structural or aesthetic, are addressed before moving to mass production.

Refining the Design Based on Feedback

The testing phase often reveals areas for improvement. Perhaps the opening mechanism is too difficult to operate, or the packaging doesn’t provide adequate protection during shipping. Based on the feedback received, the design team makes the necessary adjustments to the CAD model. This iterative process of testing and refinement is essential to ensure that the final packaging meets all the required standards.

These changes might involve altering the dimensions of the packaging, reinforcing certain areas, or modifying the closure system. The graphic design may also be tweaked based on user feedback, perhaps adjusting the color scheme or typography to improve readability. The goal is to create a packaging solution that is not only visually appealing but also highly functional and user-friendly. It’s a process of continuous improvement, driven by data and feedback.

Preparing for Production

Once the prototype has been thoroughly tested and refined, the design is finalized and prepared for mass production. This involves creating detailed technical specifications, including the dimensions, materials, printing methods, and any special finishing requirements. These specifications are communicated to the packaging manufacturer, who will then set up the production line.

The manufacturer may also create a small batch of pre-production samples to ensure that the final product meets the agreed-upon standards. These samples are carefully inspected for any defects or inconsistencies. Only after the pre-production samples have been approved does full-scale production begin. The transition from prototype to mass production is a critical step, requiring close collaboration between the design team and the manufacturer.

Sustainability Considerations

In today’s world, sustainability is no longer a niche concern; it’s a core business imperative. Consumers are increasingly demanding eco-friendly packaging, and brands are responding by adopting more sustainable practices. This includes using recycled materials, reducing packaging waste, and designing for recyclability.

The design phase offers many opportunities to improve the sustainability of packaging. This could involve minimizing the amount of material used, choosing materials with a lower environmental impact, or designing the packaging so that it can be easily recycled or composted. For example, a designer might opt for a single-material construction, making it easier for consumers to recycle the packaging. They might also choose to use vegetable-based inks or water-based adhesives, reducing the use of harmful chemicals.

The Future of Packaging Design

The field of packaging design is constantly evolving, driven by technological advances, changing consumer preferences, and a growing awareness of environmental issues. New materials, printing technologies, and design software are continually emerging, offering exciting new possibilities for creating innovative and sustainable packaging solutions.

Smart packaging, which incorporates sensors and other technologies to track and monitor the product, is also gaining traction. This technology can provide valuable data on the product’s condition, location, and even its authenticity. The integration of digital technologies, such as QR codes and augmented reality, is also transforming the way consumers interact with packaging. These technologies can provide access to additional product information, promotional offers, or even interactive experiences. Packaging design is becoming more than just a container; it’s becoming a key part of the overall product experience. The use of 3-D modeling softwear is becoming more advanced, allowing for more intrecate and complex designs.